FAMILY BUSSINES

A modern European company with a vision of being a

“co-creator in Industry 4.0”

We founded ETRA in 1994. Today we are a medium-sized company with more than 70 employees.

In 2001, we obtained the “Siemens solution partner” certificate with our specific knowledge in the field of control and monitoring systems. By expanding the structure of tubs and activities, investing in the development and implementation of quality services, we have entered a framework where we enable the production of intelligent production systems. We combine knowledge from machine design to turnkey solutions under one roof.

We offer unique solutions, that are a result of many years of experience and the use of the latest technologies and discoveries in the field of mechanical engineering. In our history, we have developed many unique and recognizable solutions, for which we have received many awards for innovative solutions.

CONTACTTurnkey solutions

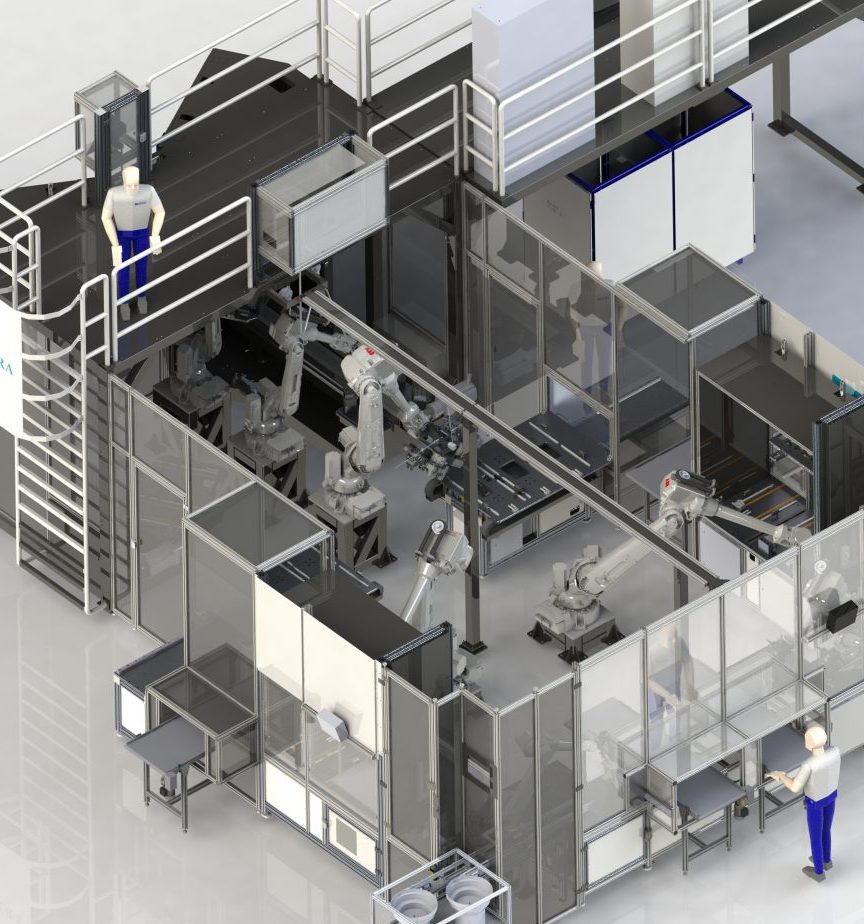

Robust, high-quality processes for creating new products and services and production processes are the result of an inter-functional and inter-departmental approach to planning. Using virtual models, our own knowledge and simulation tools, we optimize products to achieve higher productivity already in the design phase. Our production process is adapted to small series or individual production and takes place in our own premises.

1

CONCEPT and DESIGN OF THE PROJECT

We draw conceptual designs, construct entire assemblies and lines, unique industrial solutions and systems, prepare 3D models and simulate operation.

2

PRODUCTION and TAKEOVER

We perform mechanical and electrical assembly, disassembly and assembly at the customer’s location, automate the line, integrate into the existing system, test operation and perform commissioning and hand over for use.

3

MAINTENANCE and OPTIMIZATION

We perform on-duty 24/7 predictive and curative maintenance of all our industrial production systems and solutions and take care of the optimal operation of industrial processes.

Among the leaders in the field of intelligent manufacturing systems (IPS)

The construction of IPS – smart production plants (mechanical engineering) is one of the main activities of our company. We offer the client turnkey production and integration into the existing business system.

Solutions are the fruit of your knowledge

Wise solutions for easy management and higher productivity.

PROCESS TECHNOLOGICAL LINES

We manufacture palletizing, depalletizing, logistic, wrapping, packaging, palletizing, dosing, weighing, handling and other complementary systems.

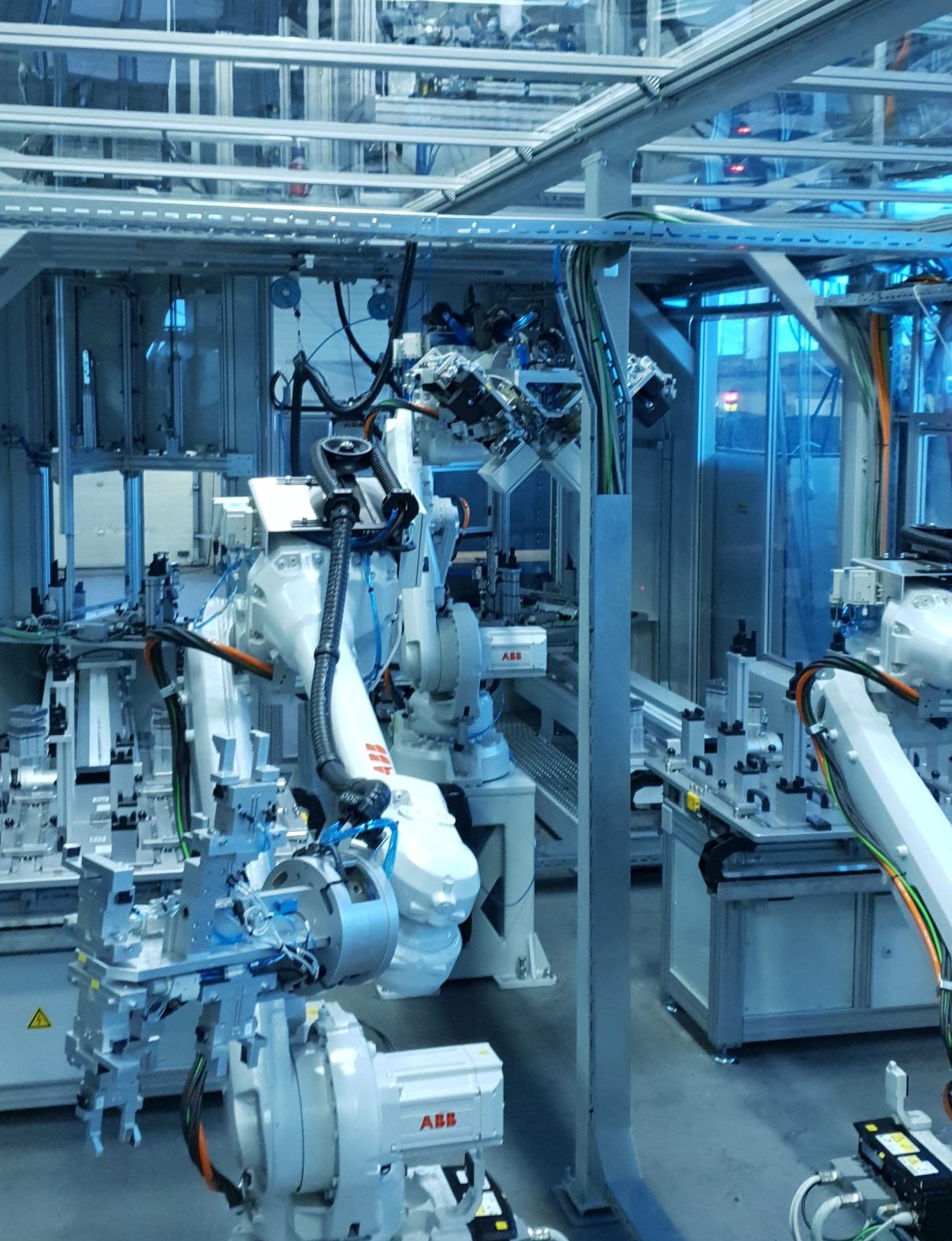

SPECIAL ROBOTIC CELLS

We manufacture dedicated robotic cells with complex processes of assembly, manipulation, testing and control.

DEDICATED PRODUCTION MACHINES

We manufacture specific and unique machines according to the wishes, needs and requirements of the client, such as punching, gluing and welding cells, bending machines, flying saws and the like.

We perform software adjustments in the field of mechanical engineering, automation, robotics and digitalization

Regardless of the development of the client’s digital productions, we create a digitized control system that enables online monitoring of production, and in a more demanding implementation also analytical management of production, which is an indispensable component towards Industry 4.0.

We develope software solutions

Smart solutions to achieve a higher level of digitization.

CONTROL AND MONITORING SYSTEMS

We implement control and monitoring applications for production automation within our own developed application solutions and within the Siemens Automation partnership.

CONTROL (VISION) SYSTEMS

We perform machine vision control systems to detect, identify and control elements or final product controls.

ROBOT APPLICATIONS

In the field of robotics, we are partners of all recognized brands of robot manufacturers and run applications for industrial and collaborative robots.

SOFTWARE APPLICATIONS

We offer the creation of dedicated software applications at the request of the client, where we enable the connection of systems at all levels of digitization.

Many years of experience in the field of digitalization of companies

We are creating new ways of digitization and connecting with research institutions for a constant step with progress and establishing new factories of the future. We train staff to manage new technologies in a real environment and unlock digital thinking.

We advise, improve and digitize.

Real investments and direct improvements based on wise advice.

TO THE FACTORY FUTURE

We offer comprehensive consulting for the transition to a new era of Industry 4.0 and prepare solutions for implementation.

IMPROVEMENTS FOR HIGHER PRODUCTIVITY

We advise companies in the field of digitalization, optimization and connectivity of processes to achieve greater efficiency, higher productivity and faster implementation of processes.

INTRODUCTION OF COLLABORATIVE ROBOTICS

We advise in the field of creating hybrid jobs and introducing advanced technological solutions.

Maintenance remains our passion throughout

Our company was founded in 1994, with the aim of operating in the field of industrial electronics, maintenance and expansion in the field of industrial process automation. Since then, we have maintained and today offer modern predictive and curative maintenance services.

We maintain and repair.

Smart maintenance for long-lasting operation.

INDUSTRIAL ELECTRONICS

We offer maintenance of systems or certain sets of industrial electronics systems.

PROPULSION TECHNIQUE

Depending on the environment, power and accuracy, we advise and design control techniques from various manufacturers.

REMOTE CONTROL OF ELEVATORS

We perform upgrades on all devices and machines (construction cranes, bridge cranes, freight cranes, industrial cranes, concrete mixers, pumps, concrete conveyor belts, car cranes,…).

COGENERATIONS

We maintain cogeneration units manufactured by TEDOM.

Our priority is quality

We have ISO 9001 and ISO 14001 certificates.

We install quality and sustainable industrial equipment.

We are certified partners for Siemens and TEDOM, as well as ABB, KUKA and FANUC certified partners in the field of robotics